Sandbox

What is SKU and MOQ? A Beginner’s Guide to Inventory Basics

Understanding SKU & MOQ

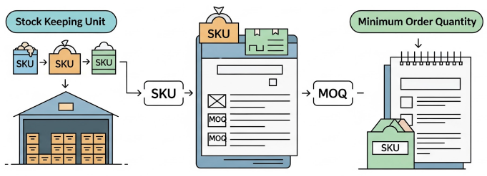

Controlling stock levels of inventories may seem like navigating through the corridors of a vocabulary puzzle. SKU (Stock Keeping Unit) and MOQ (Minimum Order Quantity) are very common terms associated with. Any retail shop, online store, or a tiny warehouse leads to these terms. Saving you and your business time, money and aggravation, comprises of a level of familiarization with these terms. This text aims to provide a definition of both terms alongside their importance to streamline your daily business functions.

1. What is an SKU?

A SKU, or Stock Keeping Unit, is a distinct identifier that companies utilize to locate every item or variation they offer. It’s similar to a useful tag that simplifies monitoring your stock. For instance, if you possess a T-shirt in three colors: Red, Blue, and Green, along with three sizes: Small, Medium, and Large. You can see how this system helps.

TSH (T-shirt). Color:

RED. Size:

M. SKU Example:

TSH-RED-M

This structured code makes it easy to scan, update, and even integrate with tools like barcode scanner, inventory apps or spreadsheets.

Why are SKUs Important?

2. Faster Operations — Staff can find, pack, or reorder items quickly when every product has a unique ID.

3. Better Data for Decisions — By analyzing SKU-level sales, you’ll know which variations sell well and which don’t. This helps you avoid dead stock.

4. Multi-channel Sync — If you sell on places like Shopify, Amazon, and in-store, SKUs make sure the same product is consistently tracked across platforms.

2. What is MOQ?

MOQ stands for Minimum Order Quantity. It’s the minimum quantity of items a supplier is prepared to sell in one order. For example, a manufacturer might set an MOQ of 500 units for a water bottle. If you only want to order 50, they won’t accept it as the minimum should be at least 500 units. MOQ is common in wholesale and manufacturing people because suppliers want to ensure that producing or shipping products is cost-effective.

Why Do Suppliers Set MOQs?

2. Profit Protection — Selling in bulk ensures the supplier isn’t losing money on small, unprofitable orders.

3. Logistics Optimization — MOQs reduce handling and shipping inefficiencies.

How MOQ Impacts Your Business

. Risk of Overstocking — Meeting MOQ could leave you with inventory that doesn’t sell quickly.

. Price Advantages — On the other hand, ordering at MOQ (or higher) often gets you a better per-unit price, which improves your margins.

3. How SKU and MOQ Work Together

Understanding SKU and MOQ side by side is important. SKUs assist in monitoring stock, whereas MOQs influence your purchasing of inventory.

For example, you could have a SKU for “Size 9 Blue Sneakers,” yet your supplier's MOQ requires you to buy at least 100 pairs of sneakers in total (various sizes and colors). Aligning demand for every SKU with the supplier's MOQ is crucial to avoid overstock.

4. Tips for Managing SKU and MOQ Effectively

2. Negotiate with Suppliers — Smaller businesses can often negotiate lower MOQs, especially if building long-term relationships.

3. Automate Tracking — Tools like barcode scanners, inventory apps, or even Google Sheets with automation can keep SKU data updated in real time.

4. Bundle SKUs Strategically — If your supplier’s MOQ is high, consider bundling items or creating product sets to move inventory faster.

In summary

SKU and MOQ might initially seem like specialized terms, yet they are merely fundamental elements of inventory management. SKU maintains your inventory organized and identifiable, while MOQ specifies the minimum amount you need to purchase from suppliers. Grasping both ideas will enable you to reduce expenses, handle your waste efficiently, and maintain a steady financial flow. This is crucial whether you are beginning your journey or aiming to expand your business. Mastering these fundamentals can assist you in steering clear of numerous operational issues.