Sandbox

Making Product Recalls Faster, Safer, and Traceable with Real-Time Data Infrastructure

Product recalls are happening more frequently, and the operational risks keep climbing. A small contamination issue or a single faulty component can ripple across thousands of units in hours. Yet many manufacturers, distributors, and retailers still rely on outdated tools that make recall execution slow, reactive, and error-prone.

Modern recall management requires real-time visibility, unified data, and tamper-proof traceability. This is where platforms like GearChain are starting to reshape the industry.

Why Recalls Break Down in Today’s Supply Chains

Most recall failures come from one core problem: fragmented and outdated data environments. Paper logs, siloed spreadsheets, legacy ERPs, and manual inputs create a slow and incomplete view of product movement.

Common flaws include:

Missing or inconsistent documentation

Paper trails and uncontrolled spreadsheets rarely provide a reliable chain of custody. Data gaps make it hard to pinpoint where an issue started or which units are affected.

Weak batch and lot-level traceability

Teams often lack visibility into supplier inputs, manufacturing runs, or downstream distribution. Without granular identifiers, companies recall entire lines instead of targeted units.

Scattered data across departments and partners

Suppliers, co-packers, warehouses, 3PLs, and retailers often maintain their own systems. During a recall, teams spend hours reconciling disconnected records.

High exposure to human error

Manual reconciliation slows everything down, increases the chance of mistakes, and introduces unnecessary risk.

A slow recall is not just an operational issue. It causes:

Safety incidents

Regulatory penalties

Waste and unnecessary product destruction

Costly lawsuits

Long-term brand damage

With global supply chains moving faster than ever, outdated recall workflows are no longer acceptable.

Transparent Tracking: The Modern Approach to Recall Readiness

Leading manufacturers and retailers are shifting toward transparent, data-driven traceability systems that provide a real-time view of a product’s lifecycle. The goal is to eliminate blind spots and make it possible to locate affected items immediately.

Key advantages include:

Real-time visibility across the entire supply chain

Teams can see where items were sourced, produced, stored, and distributed without digging through separate systems.

Immediate identification of affected batches

Instead of recalling entire categories, companies can isolate the exact units tied to a contaminated ingredient or defective component.

Reduced operational risk

Digitized traceability eliminates guesswork and lowers the chances of pulling the wrong items.

Faster communication

When something goes wrong, suppliers, distributors, retailers, and customers can be alerted within minutes.

Transparency transforms recalls from reactive events into controlled, data-driven workflows.

GearChain: Real-Time Traceability Built for Modern Recall Demands

GearChain delivers a unified approach to recall management by combining two key capabilities:

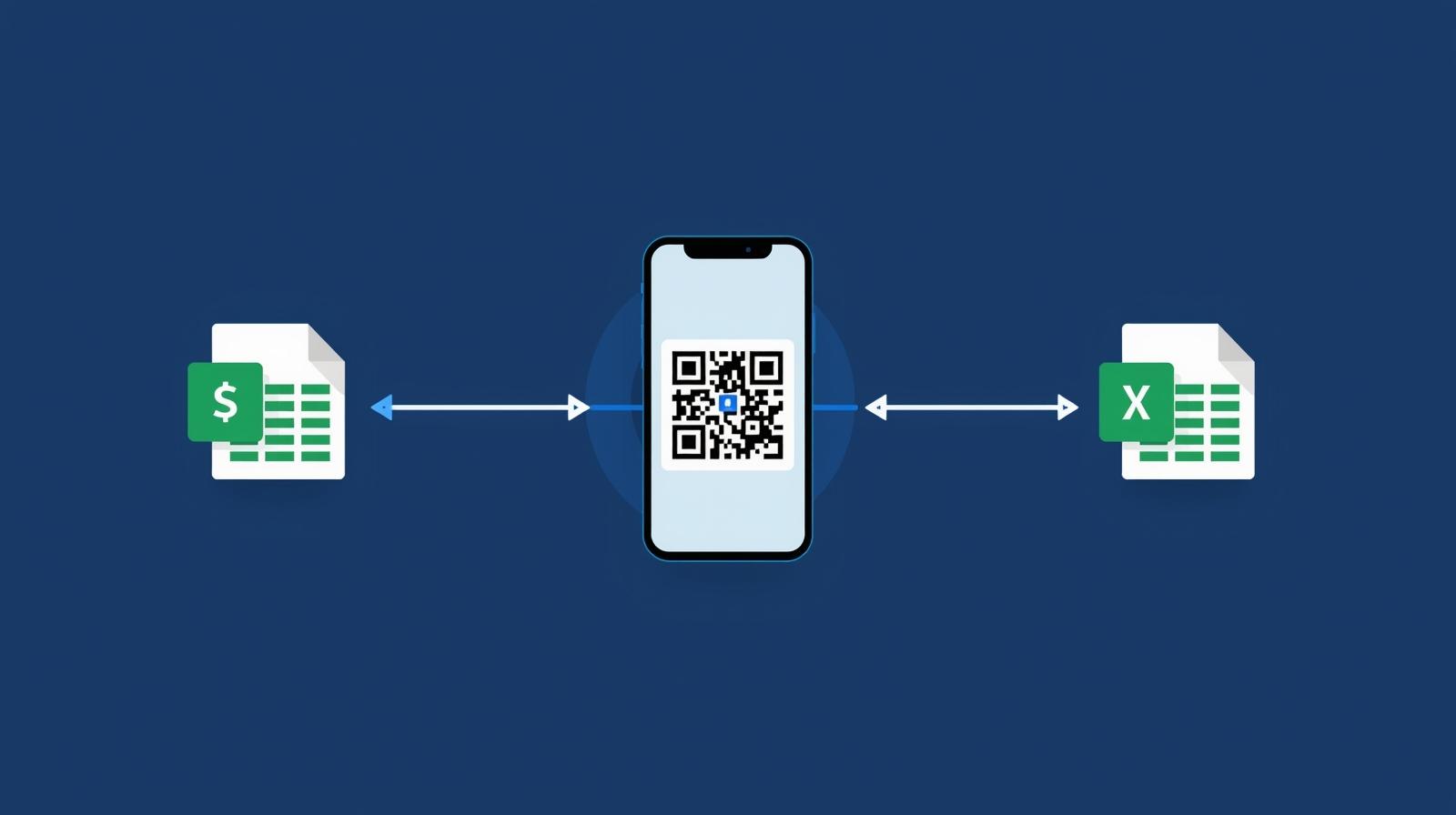

Real-time data sync with Google Sheets and Excel

Blockchain-secured traceability for tamper-proof tracking

This blend gives organizations both speed and trust, something traditional tools rarely provide.

Real-Time Spreadsheet Sync: The Missing Ingredient in Most Recall Systems

Many supply chain teams still rely heavily on Google Sheets or Excel for daily operations. The problem is that these spreadsheets often become outdated and disconnected from actual on-floor activity.

GearChain solves this directly.

Every barcode scan, update, movement, and status change syncs into Google Sheets or Excel in real time.

Not delayed. Not batch-uploaded. Truly real time.

This eliminates version conflicts, manual data entry, and delays between field teams and central operations.

Why this matters during a recall:

QA, compliance, and operations teams always work from the same, most recent dataset.

No one needs to chase down updated versions of spreadsheets.

Field staff can update items directly from the app, and leadership sees the results instantly.

Recall decisions become data-driven instead of assumption-driven.

Real-time spreadsheet integration does more than streamline workflows. It raises the integrity and reliability of the entire recall process.

Blockchain-Backed Traceability

Every scan captured in GearChain is recorded on a blockchain ledger, creating a tamper-proof audit trail of the item’s movement and status history.

This ensures:

Accurate product histories

Trustworthy batch and lot tracking

No data alteration or backdating

Full transparency across partner networks

Blockchain becomes the verification layer that proves data integrity, while real-time spreadsheet sync ensures speed.

Digital Product Passports for Every Item

Each item stores:

Manufacturing details

Batch and lot data

Ingredient or component inputs

Distribution path

Handoffs and ownership transfers

Activity logs and quality checks

This enables instant root-cause analysis and batch-level isolation during a recall.

Supplier-to-Retail Visibility Without System Overhauls

Because GearChain runs on mobile devices and syncs with common spreadsheets, partners can adopt it quickly without switching their ERP or WMS. Everyone works from the same verified data, which reduces friction during joint recall execution.

Automated Alerts for Rapid Response

GearChain can trigger notifications to distributors, warehouses, retailers, and even end consumers. This ensures unsafe items are removed from circulation as fast as possible.

Benefits of GearChain for Recall Operations

Speed: Identify affected units in seconds instead of days.

Precision: Only the impacted batches are pulled.

Compliance: Aligns with global traceability and safety standards.

Cost Efficiency: Reduces waste, prevents over-recalling, avoids litigation.

Trust and Accountability: A single, verified source of truth improves coordination across partners.

Operational Flexibility: Works with your existing spreadsheet workflows, not against them.

The Future of Recall Management: Real-Time, Data-Driven, and Transparent

Supply chains are getting more complex, regulations are tightening, and customer expectations are rising. Companies can no longer rely on reactive recall processes.

Systems like GearChain enable teams to:

Track products across their complete lifecycle

Detect issues early

Execute targeted recalls with confidence

Protect both consumers and brand reputation

GearChain positions organizations to act with speed and certainty, not assumptions and delays.